Coal mining contributes 71.3% of primary energy and supports 66% of Indonesia’s electricity production. However, with the 2050 renewable energy mix target set at 31%, the position of coal is increasingly being questioned.

Amid the pressure of the energy transition, PT Golden Energy Mines Tbk (GEMS) has consistently increased its coal production year after year.

Data and Trends in Indonesia’s Coal Production

Over the past five years, Indonesia’s coal mining industry has continued to record production surges. From 616 million tons in 2018 to 836 million tons in 2024, this trend reflects market demand—particularly from the still-dominant export sector.

|

Year* |

Domestic Production |

Domestic (million tons) |

|

2020 |

563.73 |

131.89 |

|

2021 |

613.99 |

133.04 |

|

2022 |

687.43 |

215.81 |

|

2023 |

775.18 |

212.87 |

|

2024 |

836.13 |

232.64 |

*Source Performance Report of the MEMR year 2024

The increasing production trend demands a stronger commitment to sustainable and accountable mining practices.

The implementation of Good Mining Practice is no longer an option but a necessity to maintain a balance between production performance and domestic demands as well as environmental impacts.

Coal Mining Operations at PT Golden Energy Mines Tbk (GEMS)

In the Indonesian coal mining landscape, geology is more than just a map of the land. Its presence determines the type of coal and extraction methods, as well as the potential of coal resources.

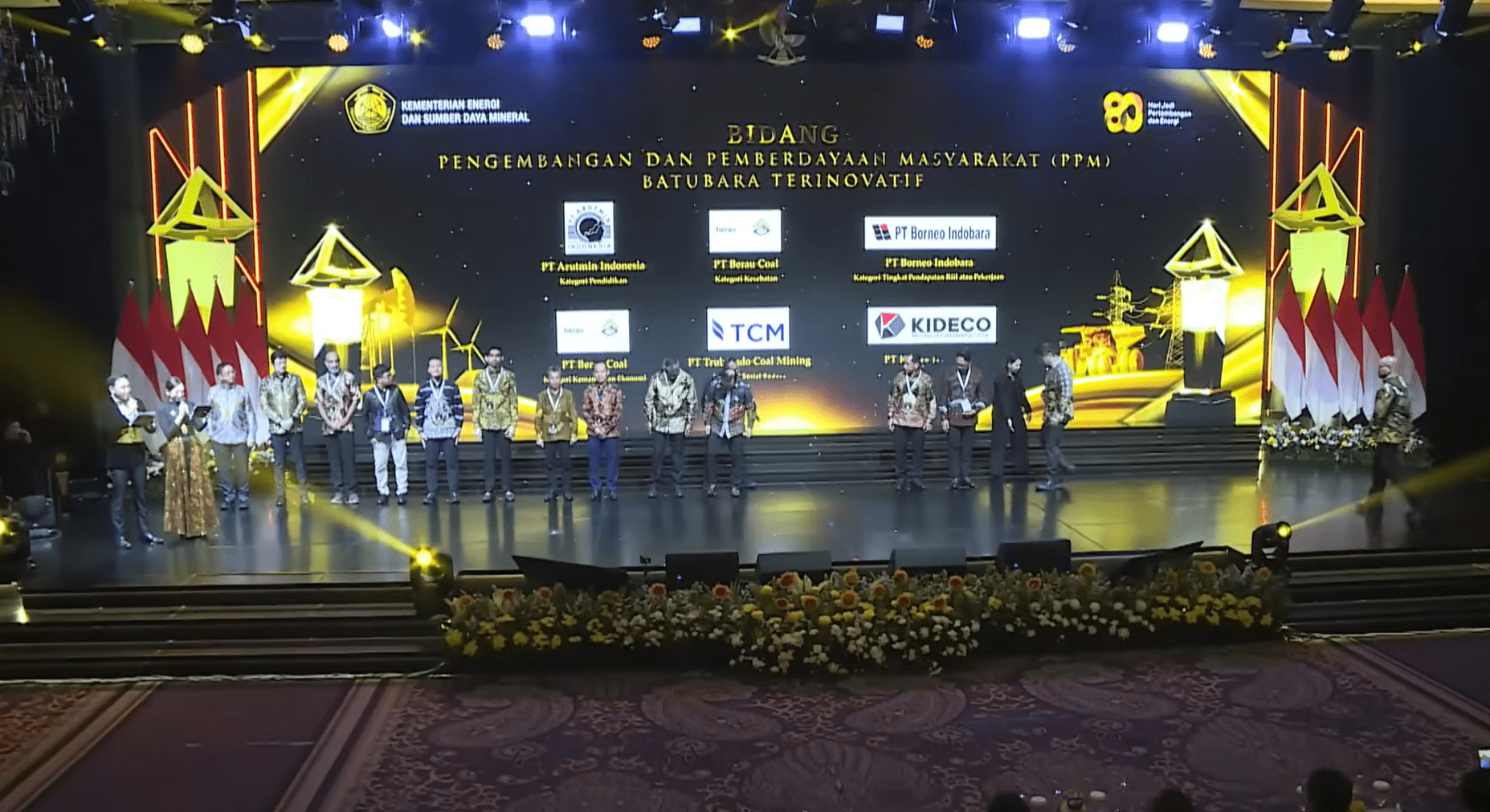

Through the CCOW (Coal Contract of Work) scheme, GEMS manage a concession area in South Kalimantan which is rich in sub-bituminous coal through its subsidiary, PT Borneo Indobara (BIB). This is a type of coal with medium calorific value and is sought after by the Asian market for power plants.

GEMS Mining Process: Efficient, Measurable and Regulation Compliance

GEMS mining operations begin with land clearing and careful removal of topsoil to a designated topsoil storage site to support the post-mining reclamation process.

Next, overburden is stripped, followed by systematic mining activities, integrated with a focus on occupational, health, safety and environmental sustainability.

The mined coal is transported to a stockpile, crushed, and then loaded onto barges (barge loading) for distribution to domestic and export markets. The process concludes with the reapplication of topsoil, revegetation, and reclamation monitoring. With this approach, the former mining area not only recovers but also becomes productive again.

Open Pit Method

All GEMS mining areas use the open pit method. This method is the most optimal for the characteristics of Kalimantan coal, which is close to the surface.

This method’s advantages in product efficiency but also in minimal geotechnical risks. Furthermore, implementation of occupational safety systems, and relatively efficient mitigation of the environmental impacts of coal mining.

This ensures high productivity, low technical risk, and consistent environmental compliance.

Read Also: Sustainable Mining Is Not a Concept It’s a Strategy for a Greener Future

GEMS’ Commitment to Good Mining Practice and Sustainability

GEMS uphold the principles of Good Mining Practice and compliance with relevant regulations and reclamation as part of its long-term responsibility. For us, sustainable mining is a commitment in carrying out future operational activities.

Through a consistent, transparent, and responsible approach, GEMS demonstrate that coal mining can be conducted sustainably without compromising ethics and sustainability values.